Drones make aerial photovoltaic inspections easy and precise.

Why performing aerial electroluminescence inspection with drones?

Safety:

Minimize risks with aerial inspections.

Efficiency:

Quick assessment of large solar plants, reducing downtime.

Cost-effective:

Lower expenses compared to traditional methods.

Precision:

Detailed data capture for accurate analysis.

Accessibility:

Reach remote or difficult terrain effortlessly.

Consistency:

Uniform assessment across multiple sites for better management.

Aerial inspection

Working procedure.

Plant Information gathering

- Location and other physical conditions.

- Plant electrical drawings and technical specs.

- Inspection scope and purpose.

Planification

- Comprehensive working plan established, daily basis.

- Flight missions and polarization sequences determined.

- Flight permits clearance.

Moving to the plant

- Iberian peninsula by furgo.

- Overseas: technicians and equipment separately.

- Transportation of gen-set where needed together with complete inspection and polarization stuff.

Execution

- Night operations.

- H&S requirements fulfilled.

- Eventual customer collaboration (trackers positioning, auxiliary technicians, inverters EL managing... in case).

Analysis and reporting

- Leveraging CELSOS Software.

- Visualization platform or PDF reporting.

- Customer quality criteria into account.

- Next level diagnostics.

Celsos uses several estrategies

depending on the PV plant.

Utily scale plant with central inverters

String level biassing through combiner boxes (fuses maneuver).

Utily scale plant with multi-string inverters

String level biassing with Celsos switching cases.

Utily scale plant with el compatible inverters

(Ingeteam)

Entire combiner boxes biassing from Inverter control console.

Rooftop pv plant

String level biassing through combiner boxes (fuses maneuver).

Integrate photovoltaic inspection

with the best software

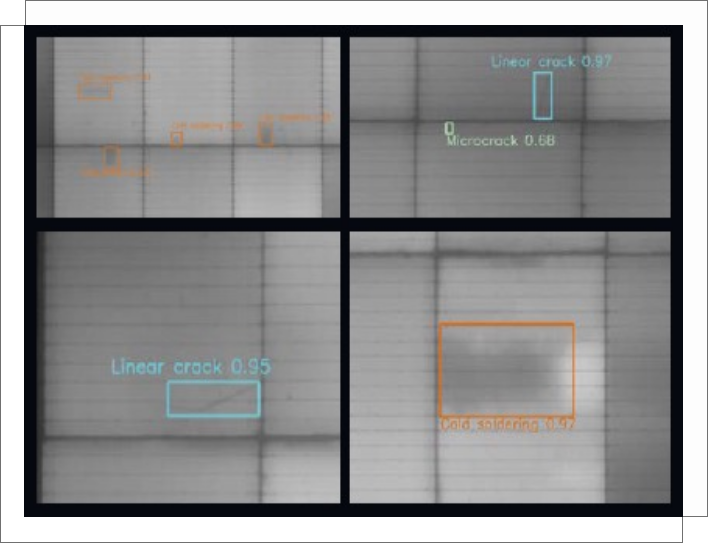

Celsos Software is a seamless composite of programming codes whose core is based on Artificial Intelligence models.

Integrate photovoltaic inspection

with the best software

EL KIT for terrestrial

inspection

We have develop an EL KIT when boundary conditions of certain inspections make drone flying not possible or not worth it.